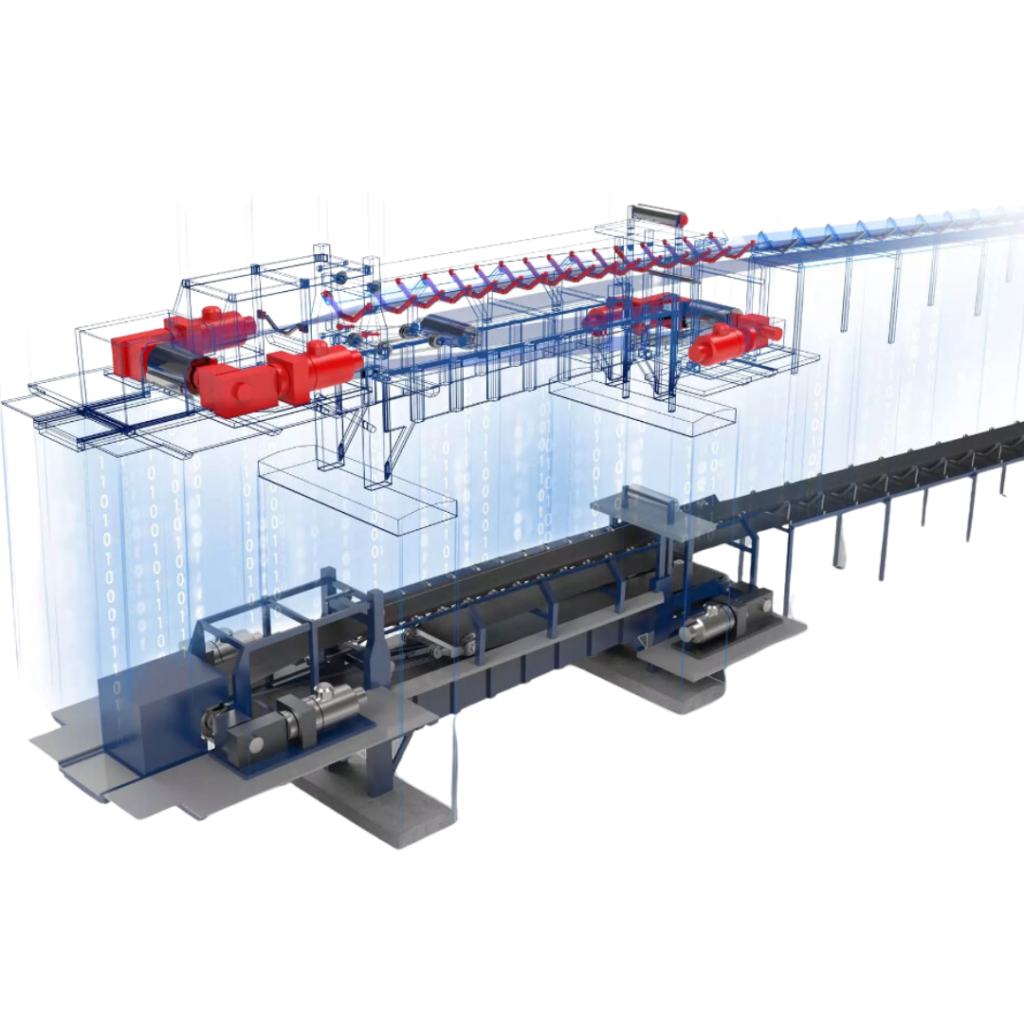

AI-based software can be used to visualize the furnace in a Digital Twin, making it easy to monitor, visualize, and find real-time insights. This software can be used to track the furnace's temperature, pressure, and other important metrics. It uses a combination of AI based image processing and IIoT data to capture Production , Detect Anomaly and Production efficiency.

Smart Monitoring, SmartMelter radar, SmartAudit, Traditional, and Digital Endoscopy, along with SmartDigital Furnace Software, create a robust system for furnace optimization. SmartRun monitors refractory conditions in real-time, SmartMelter radar provides precise molten metal insights, SmartAudit adds intelligent analysis, and Endoscopy technologies offer visual diagnostics. All seamlessly integrate into SmartDigital Furnace 4.0 Software for predictive analytics and proactive maintenance, ensuring efficient and enduring furnace performance in industrial processes.

SmartDigital Refractory Monitoring offers advanced digital oversight for furnaces. By continuously tracking refractory conditions in real-time, it provides a crucial layer of insight into the furnace's operational health. This digital solution enables proactive identification of potential issues, optimizing performance and minimizing downtime. SmartRun ensures the longevity and efficiency of furnaces, transforming traditional monitoring into a dynamic, data-driven process.

Unlike other softwares SmartDigital Furnace Monitoring Software is capable of integrating with Smart Energy Monitoring Software to Capture Date like Energy Consumed Per Part Produced , Idle Furnace Time, Energy Loss & Reasons, Energy Per 1000 Parts, etc.,

SmartAudit in a Digital Twin furnace is a sophisticated process that involves intelligent analysis and assessment of operational parameters. By leveraging advanced analytics within the Digital Twin framework, SmartAudit scrutinizes real-time data from sensors and performance indicators. This intelligent audit capability enables the identification of inefficiencies, anomalies, and potential issues within the furnace. The Digital Twin, enhanced by SmartAudit, acts as a virtual inspector and continuously evaluating the furnace's performance against optimal benchmarks. This proactive approach allows for timely adjustments, contributing to improved efficiency, reduced downtime, and enhanced overall performance in industrial processes.

Traditional Endoscopy in a digital furnace utilizes endoscopic tools for visual inspections, providing direct insights into internal conditions. Integrated into the digital framework, it enhances diagnostic capabilities, aiding maintenance and optimization with real-time visual data.

Digital Endoscopy in a digital furnace employs advanced imaging technology for real-time internal inspections. This digital approach enhances diagnostics, offering high-resolution visuals of furnace components. Integrated into the digital framework, it provides valuable data for analysis within the Digital Twin system, contributing to proactive maintenance.

SmartDigital Furnace 4.0

The Digital Twin for furnace software revolutionizes furnace management, systematically monitoring risk and asset utilization. This empowers key stakeholders with unparalleled visibility, fostering informed, data-driven decisions on furnace health and maintenance. The platform establishes a comprehensive digital corporate furnace memory, laying the foundation for a sustainable furnace management program. Placing data at the core of decision-making facilitates seamless onboarding for new employees, enabling them and their designated Asset Manager to optimize operational decisions for enhanced efficiency and performance.